|

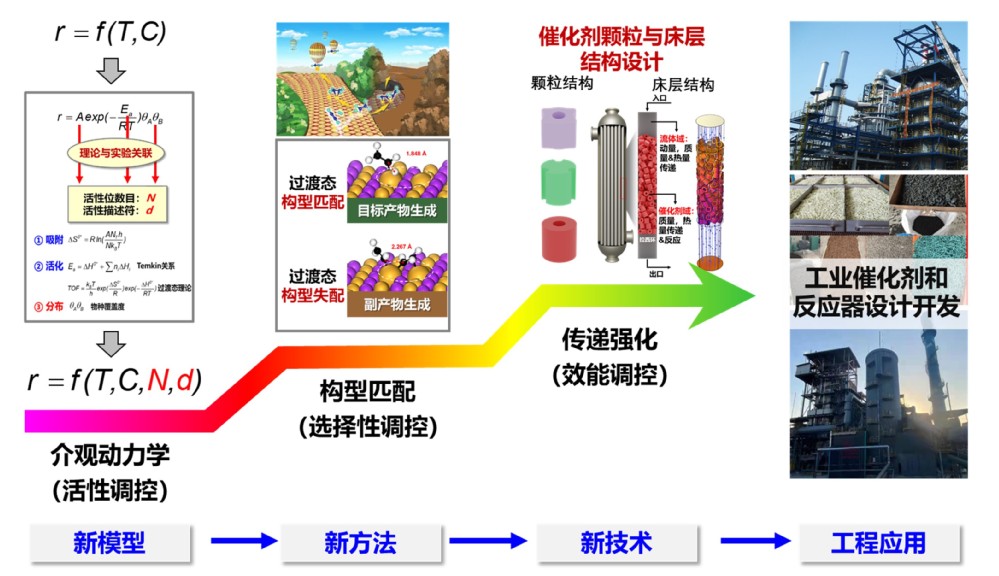

Catalytic Reaction Engineering

Catalytic Reaction Engineering focuses on the development and optimization of catalysts and reactors. This includes the design of highly efficient catalysts for various chemical reactions, such as those involving heterogeneous catalysis, as well as the preparation of structured catalysts for industrial applications. Additionally, this area emphasizes the design and optimization of chemical reactors and processes, aiming to enhance reaction efficiency and product selectivity. The group employs experimental tools, modeling methodologies, and theoretical calculations to guide the development of new catalysts and reactor designs.

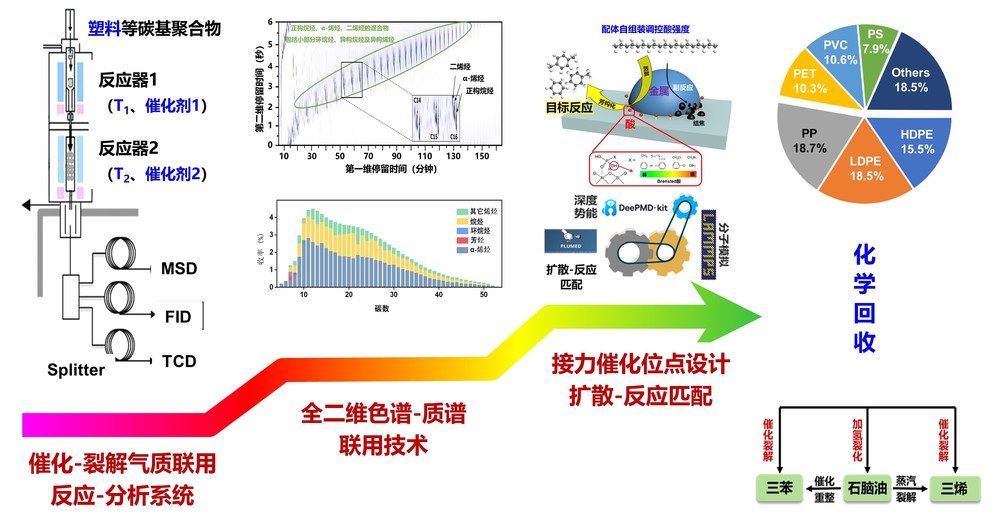

Green and Sustainable Chemical Processes

The research group is actively engaged in exploring green and sustainable chemical processes. This includes the production of commodity chemicals from non-petroleum resources, such as the catalytic conversion of biomass into high-value chemicals, as well as the development of low-carbon process technologies. The group also focuses on the recycling of waste materials, such as plastics, into useful building block chemicals through catalytic pyrolysis and other techniques. These efforts aim to reduce the environmental impact of chemical production and promote a circular economy.

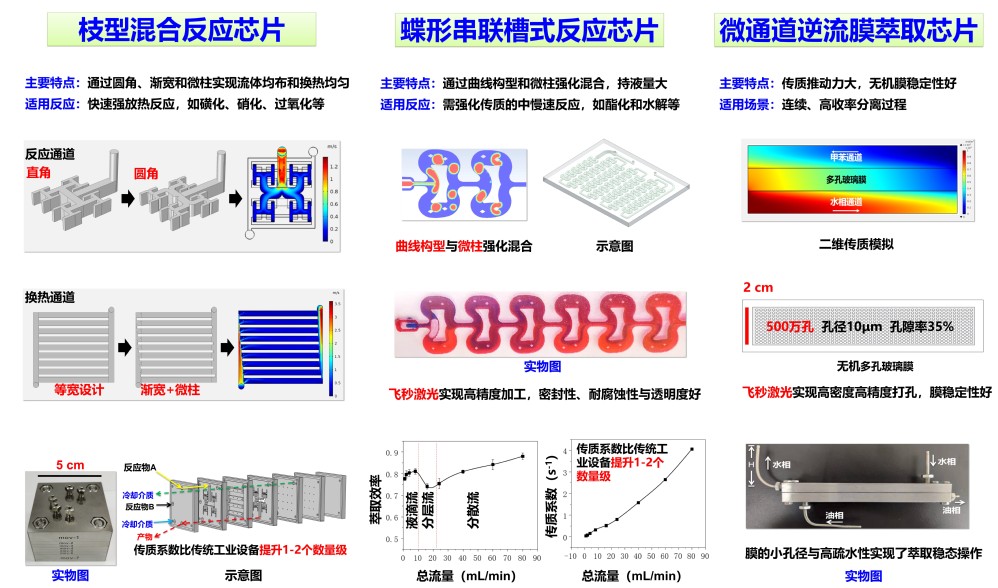

Advanced Materials and Microfluidic Technology

Advanced Materials and Microfluidic Technology is another key research area for the group. This includes the engineering of surface and interface properties of microporous catalysts to improve mass transfer and reaction efficiency. The group also designs the pellet structure of industrial catalysts using computational fluid dynamics (CFD) modeling and other techniques. Additionally, the group explores the use of microfluidic technology for process intensification, particularly in the synthesis of high-energy and highly reactive chemicals.

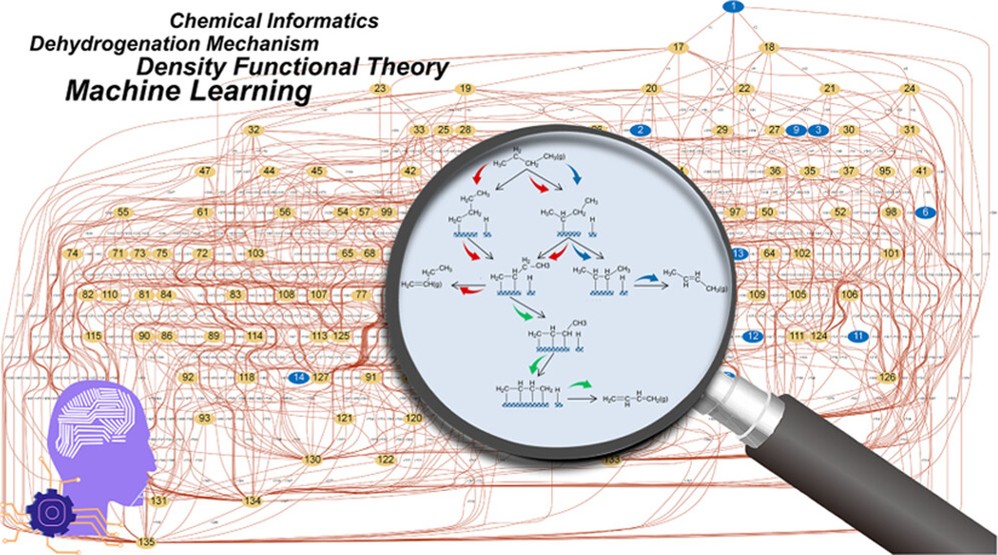

Theoretical and Computational Catalysis

Theoretical and Computational Catalysis focuses on understanding and predicting the behavior of catalysts at a fundamental level. This includes the use of density functional theory (DFT) calculations, machine learning algorithms, and microkinetic modeling to design new catalysts with high catalytic activity and selectivity. The group also employs various in situ experimental techniques and kinetics studies to characterize the structures of catalysts under reaction conditions. These efforts aim to provide a deeper understanding of catalytic processes and guide the rational design of new catalysts.

We are committed to innovation in catalysis, sustainable chemical processes, and advanced materials. By leveraging a combination of experimental, theoretical, and computational approaches, we are able to address complex challenges in the field of chemical engineering and contribute to the development of more efficient, environmentally friendly, and economically viable chemical processes.